Choose Precision.

At Providence, we offer more than just contract manufacturing services—we offer a partnership dedicated to realizing your vision with excellence.

Choose Precision.

At Providence, we offer more than just contract manufacturing services—we offer a partnership dedicated to realizing your vision with excellence.

Your Competitive Advantage

We understand how competitive the market is and that you can't afford to lose. Choosing the right manufacturer can be a make-or-break decision. That’s why we have a dedicated team of specialists ready to get your project done to spec and on time.

We could list all of our capabilities, but what you really need to know is that we are deeply committed to every partnership. Our close working relationships give our clients an advantage over their competition.

Your Competitive Advantage

We understand how competitive the market is and that you can't afford to lose. Choosing the right manufacturer can be a make-or-break decision. That’s why we have a dedicated team of specialists ready to get your project done to spec and on time.

We could list all of our capabilities, but what you really need to know is that we are deeply committed to every partnership. Our close working relationships give our clients an advantage over their competition.

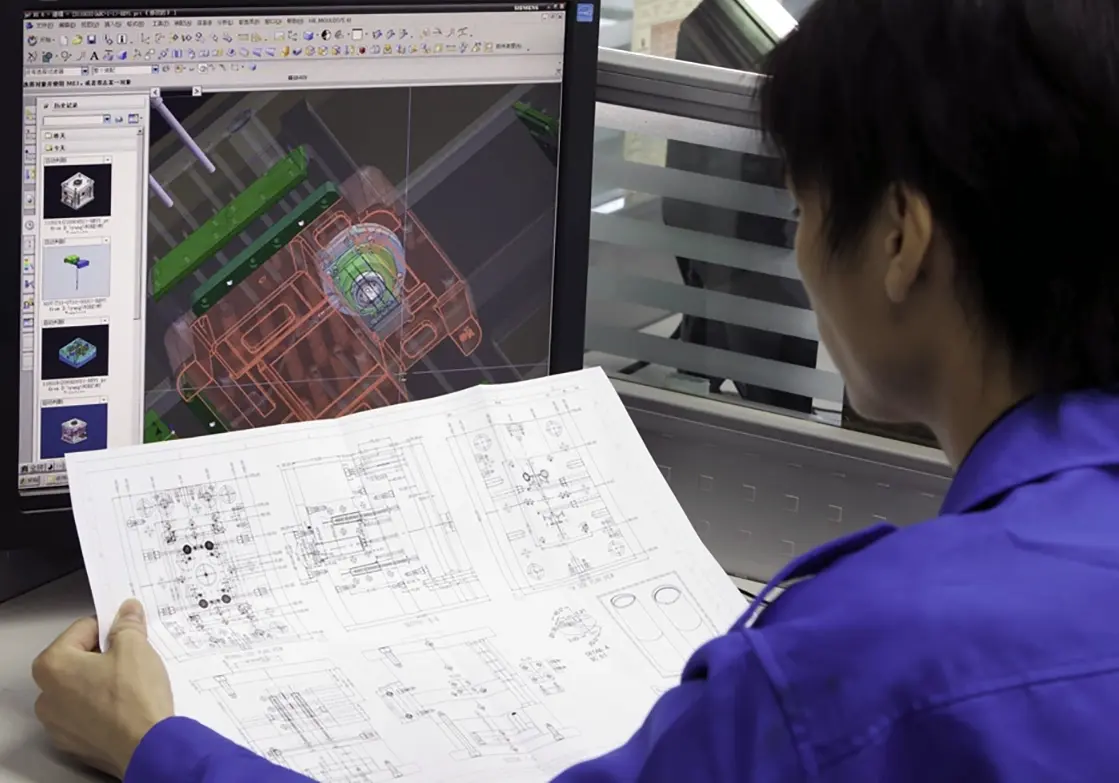

Engineering Excellence + Embracing Innovation

Our team of experts is dedicated to constantly seeking new ways to improve efficiency, quality, and performance.

With a culture that fosters creativity and collaboration, we are at the forefront of technological advancements in contract manufacturing. From concept to execution, we strive to deliver cutting-edge solutions that exceed expectations and drive success for our clients.

Learn More About How We Innovate

With a team of 65+ R&D professionals, we continually research technologies that can be integrated into our customers' products. Such technologies include:

- Internet of Things

- WiFi

- Zigbee

- Sensors

- PH Sensing

- MEMS

- Heat

- Embedded Solutions

- App Development

- Light-Based Technologies

- Touch Screen

- Battery Management

- TENS

Engineering Excellence + Embracing Innovation

Our team of experts is dedicated to constantly seeking new ways to improve efficiency, quality, and performance.

With a culture that fosters creativity and collaboration, we are at the forefront of technological advancements in contract manufacturing. From concept to execution, we strive to deliver cutting-edge solutions that exceed expectations and drive success for our clients.

Learn More About How We Innovate

With a team of 65+ R&D professionals, we continually research technologies that can be integrated into our customers' products. Such technologies include:

- Internet of Things

- WiFi

- Zigbee

- Sensors

- PH Sensing

- MEMS

- Heat

- Embedded Solutions

- App Development

- Light-Based Technologies

- Touch Screen

- Battery Management

- TENS

Industries We Serve

Medical & Healthcare

Leverage our expertise and precision to manufacture your devices with the highest standards of quality and compliance. Whether they're life-saving or life-enhancing, our commitment to excellence ensures every device we produce meets the stringent requirements of this critical sector.

Learn More

Beverage Systems

Let us serve you with tailored manufacturing solutions that combine precision engineering with cutting-edge technology. Our proficiency in this sector allows us to deliver innovative products that enhance convenience, efficiency, and user experience for consumers worldwide.

Learn More

Industrial Systems

Harness the power of excellence in manufacturing electro-mechanical industrial systems. We specialize in a range of products from highly engineered plastics to industrial pumps and motors.

Learn More

Automotive & Electric Vehicles

Choose one of the leading manufacturers of electro-mechanical automotive and Electric Vehicle components, offering product development and contract manufacturing services for automotive electronics and plastics.

Learn More

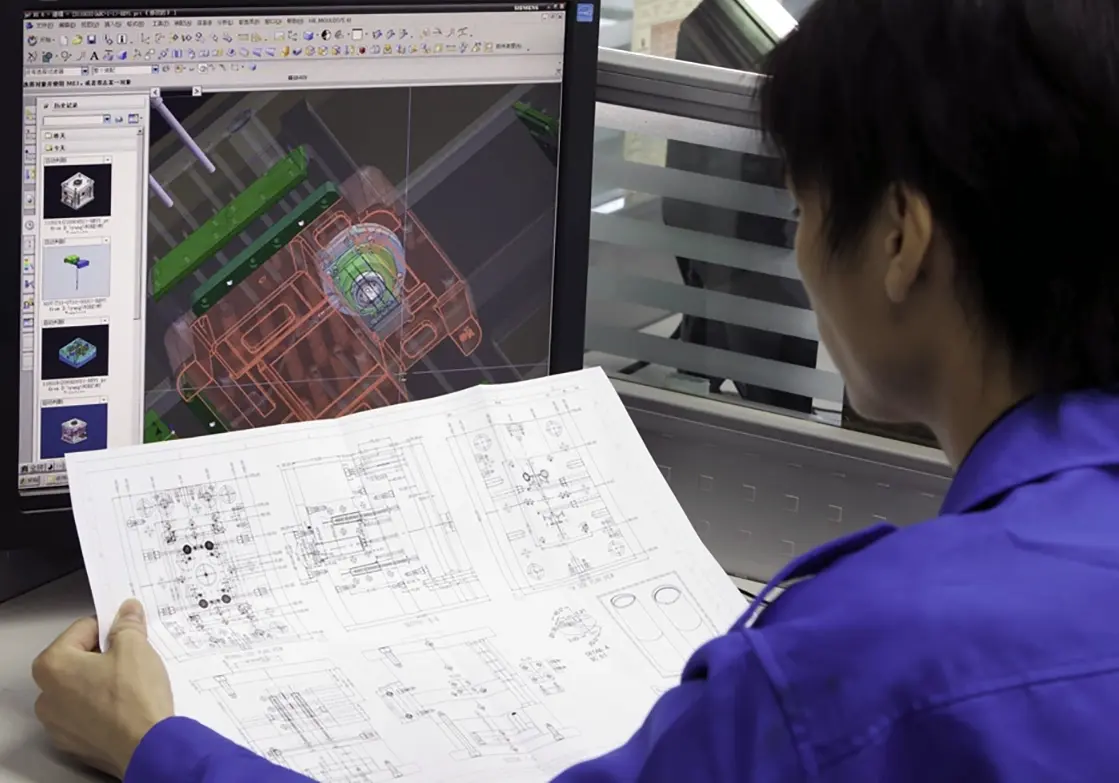

Human Robotics

As a leading contract manufacturer in the human robotics industry, we specialize in delivering high-quality components and finished good assemblies of robotic arms and legs used by people to enhance mobility.

Learn More

Industries We Serve

Medical & Healthcare

Leverage our expertise and precision to manufacture your devices with the highest standards of quality and compliance. Whether they're life-saving or life-enhancing, our commitment to excellence ensures every device we produce meets the stringent requirements of this critical sector.

Learn More

Beverage Systems

Let us serve you with tailored manufacturing solutions that combine precision engineering with cutting-edge technology. Our proficiency in this sector allows us to deliver innovative products that enhance convenience, efficiency, and user experience for consumers worldwide.

Learn More

Industrial Systems

Harness the power of excellence in manufacturing electro-mechanical industrial systems. We specialize in a range of products from highly engineered plastics to industrial pumps and motors.

Learn More

Automotive & Electric Vehicles

Choose one of the leading manufacturers of electro-mechanical automotive and Electric Vehicle components, offering product development and contract manufacturing services for automotive electronics and plastics.

Learn More

Ready to take the next step?

Start a conversation with our team to discover how we can bring your vision to life.

Quality Assurance

Our high-quality production and engineering, combined with a full range of manufacturing capabilities, allows us to deliver top-notch solutions across industries. From electro-mechanical medical devices and beverage systems to industrial and automotive components, we ensure excellence in every aspect of manufacturing.

Quality Assurance

Our high-quality production and engineering, combined with a full range of manufacturing capabilities, allows us to deliver top-notch solutions across industries. From electro-mechanical medical devices and beverage systems to industrial and automotive components, we ensure excellence in every aspect of manufacturing.

Certified for Your Peace of Mind

Our certifications are a testament to our unwavering commitment to quality and compliance: ISO 27001, ISO 13485, ISO 14001, ISO 14971, SA8000 (Bureau Veritas), ISO 9001, ISO 45001, IATF 16949, and FDA & NMPA registration.

View & Download Certifications ↓

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Certified for Your Peace of Mind

Our certifications are a testament to our unwavering commitment to quality and compliance: ISO 27001, ISO 13485, ISO 14001, ISO 14971, ISO 9001, ISO 45001, IATF 16949, SA 8000, and FDA & NMPA registration.

View & Download Certifications ↓

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Client Testimonials

I’ve worked with contract manufacturers who have state-of-the-art equipment and facilities but can’t hit a development schedule. With Providence, it’s a strong collaborative partnership. They ask the right questions and we never wonder if they’re sitting on their hands.

Mike K., Director of Sourcing

at a Global Aquatics Company

Even though I only know 8 words of Chinese, I’ve never run into a language problem in the last 6 years working with Providence. Aside from needing to schedule our phone calls at either the beginning or the end of the day, there’s no difference doing business with Providence than doing business in the US.

Jeffrey Z., VP, Operations

at a Medical Device Company

When I was searching for a new contract manufacturer, it was easy to find tons of contract manufacturers that have certifications and documentation standards that live in a filing cabinet - but my question was, “Do they actually live it?” We’ve seen this to be the case with Providence - they deliver on their promises - they are who they say they are.

Michelle P., Senior Manager of Sourcing

at a Health & Wellness Products Company

I’m an R&D guy, so it’s important to me that our supply partner is experienced in both design and production. I need someone who I can talk on the same level during the development and ongoing production. That’s been the case while working with the engineering team at Providence and I’ve appreciated the collaboration and teamwork.

Daniel D., R&D Leader

at a Health Care Company

I’ve worked with contract manufacturers who have state-of-the-art equipment and facilities but can’t hit a development schedule. With Providence, it’s a strong collaborative partnership. They ask the right questions and we never wonder if they’re sitting on their hands.

Mike K., Director of Sourcing

at a Global Aquatics Company

Even though I only know 8 words of Chinese, I’ve never run into a language problem in the last 6 years working with Providence. Aside from needing to schedule our phone calls at either the beginning or the end of the day, there’s no difference doing business with Providence than doing business in the US.

Jeffrey Z., VP, Operations

at a Medical Device Company

When I was searching for a new contract manufacturer, it was easy to find tons of contract manufacturers that have certifications and documentation standards that live in a filing cabinet - but my question was, “Do they actually live it?” We’ve seen this to be the case with Providence - they deliver on their promises - they are who they say they are.

Michelle P., Senior Manager of Sourcing

at a Health & Wellness Products Company

I’m an R&D guy, so it’s important to me that our supply partner is experienced in both design and production. I need someone who I can talk on the same level during the development and ongoing production. That’s been the case while working with the engineering team at Providence and I’ve appreciated the collaboration and teamwork.

Daniel D., R&D Leader

at a Health Care Company

Are We A Good Fit?

At Providence, we understand the need for trust and control when outsourcing. Our ISO-certified processes and global IP protection ensure security and reliability. We prioritize your goals, values, and success, fostering long-term partnerships with proactive solutions for growth and competitiveness. Trust Providence for quality, cost-effectiveness, and future-oriented strategies in contract manufacturing. Read more about how Providence is, or isn't, a good fit for your manufacturing needs.

Sound like a good fit?

Are We A Good Fit?

At Providence, we understand the need for trust and control when outsourcing. Our ISO-certified processes and global IP protection ensure security and reliability. We prioritize your goals, values, and success, fostering long-term partnerships with proactive solutions for growth and competitiveness. Trust Providence for quality, cost-effectiveness, and future-oriented strategies in contract manufacturing. Read more about how Providence is, or isn't, a good fit for your manufacturing needs.

Sound like a good fit?

-

Planning

Discover the ease of working with us at every stage of manufacturing.

Learn More → -

Development

Experience seamless collaboration at every manufacturing stage with us.

Learn More → -

Verification

Unlock a hassle-free manufacturing experience with us every step of the way.

Learn More → -

Pre-Production

Simplify your manufacturing journey with us by your side at every stage.

Learn More → -

Production

Experience a smooth journey through all manufacturing stages with us.

Learn More →

Discover the ease of working with us at every stage of manufacturing.

Learn More →

Planning

In the planning phase of our partnership, we take a comprehensive approach to understand your project requirements, goals, and timelines. Our team conducts thorough assessments to identify potential challenges and opportunities, allowing us to develop a customized plan that aligns with your vision. With clear communication and transparent collaboration, we ensure that every aspect of the planning process is meticulously addressed, setting the foundation for a successful project execution.

Experience seamless collaboration at every manufacturing stage with us.

Learn More →

Development

During the development phase of our collaboration, our team of engineering specialists brings your vision to life with precision and expertise. We leverage state-of-the-art technology and innovative methodologies to translate concepts into tangible products, while adhering to strict quality standards and regulatory requirements. Throughout this phase, we maintain open communication and provide regular updates, ensuring transparency and alignment with your project goals. Our commitment to excellence drives us to deliver optimal results and exceed expectations at every stage of development.

Unlock a hassle-free manufacturing experience with us every step of the way.

Learn More →

Verification

In the verification phase of our partnership, we meticulously test and validate every aspect of the product to ensure it meets the highest standards of quality and performance. Our team employs rigorous testing protocols and quality control measures to identify any potential issues and make necessary adjustments. With a focus on accuracy and precision, we verify that the product is ready for market launch, providing our clients with confidence in its reliability and effectiveness.

Simplify your manufacturing journey with us by your side at every stage.

Learn More →

Pre-Production

In the pre-production phase, we meticulously prepare for manufacturing by fine-tuning processes and optimizing workflows to ensure efficiency and quality. Our team conducts thorough testing and validation of equipment and procedures to identify and address any potential issues before full-scale production begins. With a focus on precision and attention to detail, we lay the groundwork for a seamless production process, ultimately delivering high-quality products that meet or exceed our clients' expectations.

Experience a smooth journey through all manufacturing stages with us.

Learn More →

Production

During the production phase, our team executes the manufacturing process with precision and efficiency, leveraging state-of-the-art technology and industry-leading practices. We maintain strict quality control measures throughout the production process to ensure consistency and reliability in every product. With a commitment to meeting deadlines and exceeding expectations, we deliver high-quality products that meet the unique needs of our clients and their target markets.

FAQ

What type of projects do you typically work on?

We specialize in product development and contract manufacturing of electro-mechanical and mechanical medical devices, beverage systems, industrial products, and automotive components. Our vertically integrated manufacturing capabilities enable us to work closely with our partners to ensure production is flexible, scalable, and yields high-performance results.

How can you help us control our costs?

Design transfer: How ready is your design for manufacturing? Some designs require more preparation for manufacturing than others. Rest assure, we guide you through this process as seamlessly as possible.

Materials and design preferences: Some companies and products require very specific materials and designs; Whereas others have a focus on performance, regardless of how it looks or what it’s made out of. Sometimes, using alternative materials, and adjusting the specific design, can help reduce your cost-per-product, without jeopardizing its performance.

Component technicality: Some products feature multiple systems that must work together. If your manufacturer is not accustomed to connecting multiple system together, the process can be challenging. Not to mention, you might still end up with a product that doesn’t work or is prohibitively expensive. Complexity does not intimidate us and electromechanical manufacturing is our specialty. We help our customers determine the most cost-effective way to bring their products to market, at scale, without jeopardizing performance.

Timeline: We have organized ourselves to be nimble. While your budget might not be as nimble, we can work with you to determine the best approach to render your compressed timeline a non-issue. For tight deadlines, we do offer an expedited approach which allows us to have multiple aspects of your project working in parallel, such as tooling, molding, SMT, and ordering materials simultaneously.

Volume and inventory: This is one of the hardest decisions many businesses have to make. You can lower your costs by ordering more, but how soon will all the units sell, and where do you store the influx in the meantime? Luckily, we have ways of helping our partners manage this process with safety stock, risk buys, and even expedited production. We can produce more units for you within two weeks if the materials are on-hand.

Ability to customize your manufacturing process: To automate, or not to automate, that is the question. Believe it or not, but it is possible to over- automate your manufacturing process. This could result in project delays and added costs. Conversely, a fully manual process doesn’t often work either, as it’s hard to maintain quality consistency, and costs can add up here as well. We help all our partners determine the correct amount of automation so that they don’t have to choose between quality consistency, speed of manufacturing, or their costs.

Testing efficiency and quality management: Mistakes cost money. This is why we have a rigorous process to test quickly and on a small scale. Our monitoring systems allow us to detect and immediately correct issues throughout the manufacturing process. This leads to an incredibly low failure rate of 0.05% which means your budget is utilized in the most efficient way possible.

With your different locations, how do you manage language barriers?

How do you maintain a high-degree of quality?

We collect data throughout the manufacturing process to monitor for issues and performance. Such data includes: Test Data, Batch Data via RFID or Barcode, Networked production lines, collect data on injection molding systems.

We have cameras set up to watch the entire process, especially for key areas which include molding, soldering, and assembly.

How soon can issues be detected, and corrected? Immediately! The constant supervision of the process allows us to act quickly, helping to preserve the timeline and budget.

What’s your rejection rate? Less than 500 defective parts per million; This results in producing very little scrap material and reducing costs.

How big are the batches that you test? We follow ISO and AQL standards.

We collect data throughout the manufacturing process to monitor for issues and performance. Such data includes: Test Data, Batch Data via RFID or Barcode, Networked Production Lines, and Injection Molding efficiency.

Do you require companies of a certain size to work with you?

Can you give me an example of some product categories and specific products you have helped create?

Oral Care: Electric Toothbrushes, Electric Flossers, Disposables, Accessories

Respiratory: Nebulizers, Ventilators, CPAPs & BiPAPs, Oxygen Concentrators, Anesthesia Equipment, Disposables

Drug Delivery: Infusion Pumps, Drug Delivery Pumps, Pharmaceutical Drug Delivery, E-Vapor Devices

Diagnostics: Disposables, Testers, Cardiac Monitors, Blood Collection, Accessories

Light-Based Devices: Hair Growth, Hair Removal, Skincare, Environment Control

Personal Health: TENS Units, Skin Beautification, Cellulite Reduction

Want a Preview of What It’s Like to Work With Us?

Get an exclusive look into our factory, processes, and people, so you can manufacture your product with confidence.

Want a Preview of What It’s Like to Work With Us?

Get an exclusive look into our factory, processes, and people, so you can manufacture your product with confidence.

%20V2.png?width=212&height=300&name=GB%20T%2019001-2016%20ISO%2090012015%E6%A0%87%E5%87%86--%E9%87%91%E8%BF%9B%E7%A7%91%E6%8A%80(%E4%B8%AD%E8%8B%B1%E7%89%88%E8%AF%81%E4%B9%A6)%20V2.png)